MTE-RCS complex cavity target RCS characteristic simulation software

MTE-RCS complex cavity target RCS characteristic simulation software

Use multiple parallel acceleration technologies and unique geometric blanking algorithms to improve computing efficiency

ABOUT software

MTE-TCS is a high-efficiency simulation software for RCS characteristics specially developed for electrically large-scale cavity-containing targets (including nozzles, inlets, etc.). The software can adaptively select appropriate calculation methods to solve according to the different scattering mechanisms of the defined components. And adopt a variety of parallel acceleration technologies and unique geometric blanking algorithms to improve computing efficiency. Due to the clear positioning, this software has obvious advantages in applicable objects and computing efficiency compared with competing products on the market.

Special feature

The grid is automatically divided according to the input frequency settings, component characteristics calculation, coating absorption material calculation, arbitrary combination of multiple high frequency algorithms, high and low frequency algorithm coupling solution, automatic report generation

Simulation accuracy

After multiple sets of standard models and equipment measured data verification, simulation accuracy ≥80%

Frequency Range

S-band, C-band, X-band, KU-band

input Output

Input requirements: CAD geometry file or .msh mesh file

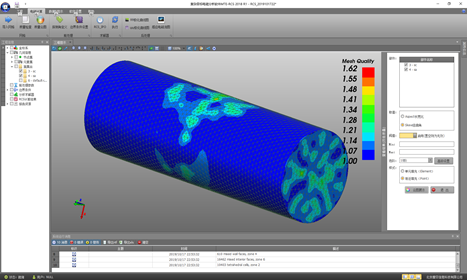

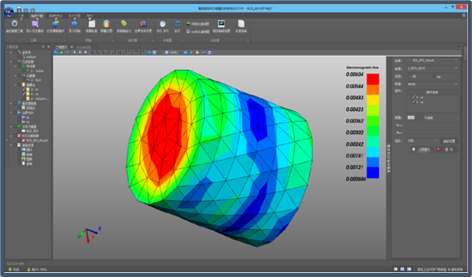

Output results: strong scattering components, wall-induced electromagnetic flow distribution cloud diagram, overall and sub-component RCS characteristic curves

Radar stealth scheme design, analysis, evaluation, etc. for various types of aircraft, missiles, helicopters, engines, etc.

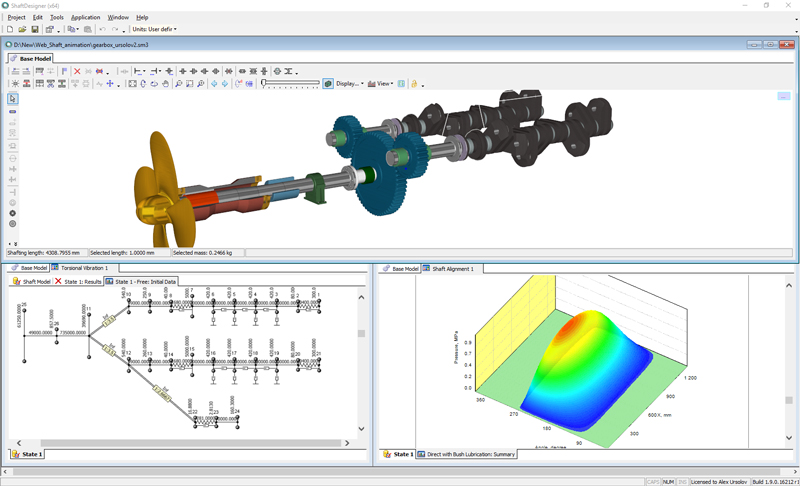

Software interface display

The main function

The main functions of target infrared characteristic simulation analysis software MTE-IRSimuator V2.0 are:

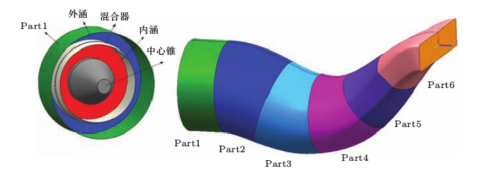

Research on the Influence of Medium Coating Position on RCS Characteristics of Double S-Bend Exhaust System

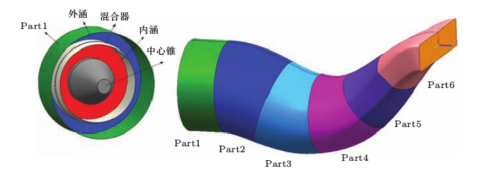

- Schematic diagram of medium coating area

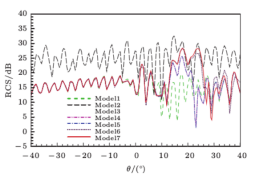

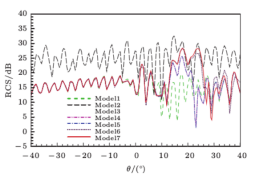

- Vertical polarization RCS distribution curve of pitch detection surface

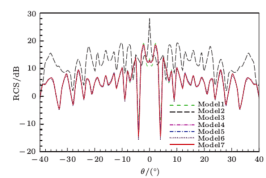

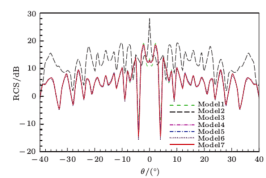

- RCS distribution curve of vertical polarization of horizontal detection surface

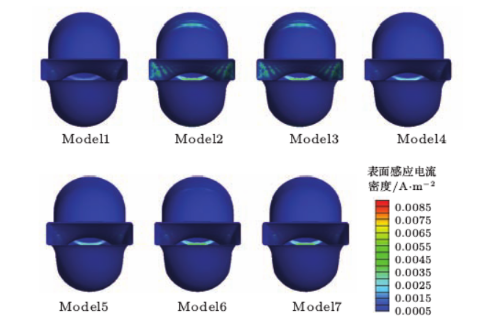

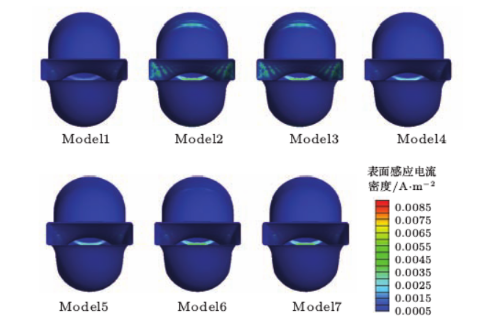

- The distribution of the induced current density of each model of the vertical polarization horizontal detection surface

Research on the Influence of Medium Coating Position on RCS Characteristics of Double S-Bend Exhaust System

- Schematic diagram of medium coating area

- Vertical polarization RCS distribution curve of pitch detection surface

- RCS distribution curve of vertical polarization of horizontal detection surface

- The distribution of the induced current density of each model of the vertical polarization horizontal detection surface